The BINGSHAN Adiabatic Cooler (also known as Adiabatic Dry Cooler or Closed Circuit Fluid Cooler) technology offers significant benefits over traditional water-cooled systems, including:

Eliminating the risk of Legionella;

Lower water consumption (reduced by 75% compared to conventional cooling towers);

No water treatment chemicals required;

Compliance is simplified (no RMPs or regular audits needed).

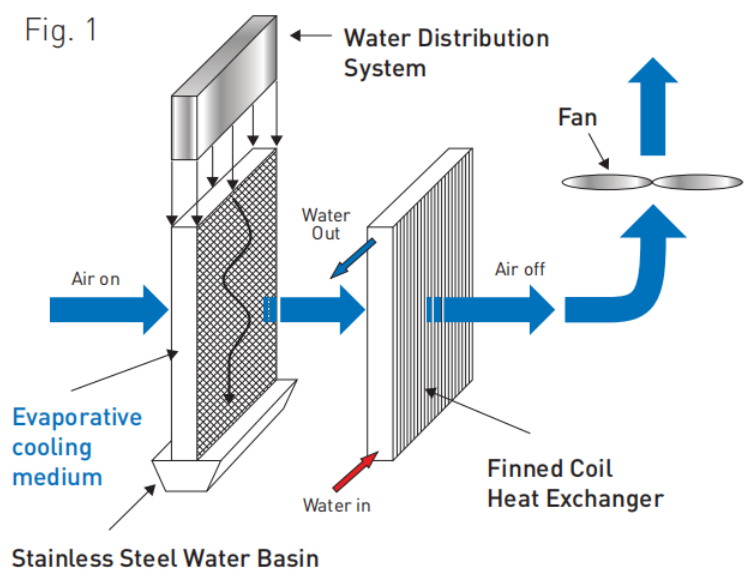

The BINGSHAN Adiabatic Cooler units comprise:

Two vertically finned tube heat exchanger coils (common in Closed Circuit Coolers);

Two sets of evaporative pre-cooling pads (key to Adiabatic Cooling efficiency);

A bank of low-noise axial flow fans;

A water distribution system for air pre-cooling, including a circulation pump, water make-up solenoid, and motorized dump valve;

A Programmable Logic Controller (PLC) for automated operation.

The Adiabatic Cooling system leverages the adiabatic principle of heat rejection, combining the benefits of dry cooling and evaporative cooling:

Dry Mode: Under moderate ambient temperatures (<20°C), the system operates as a Closed Circuit Cooler, using only air to dissipate heat.

Adiabatic Mode: At high ambient temperatures (>20°C), water is sprayed onto the pre-cooling pads, reducing air temperature through evaporation (Adiabatic Cooling). This cooled air then passes over the heat exchanger, enhancing efficiency by 30-40% compared to standard air-cooled systems

1.Water Efficiency: Unlike traditional cooling towers, Adiabatic Dry Coolers use water only when necessary, reducing consumption by 75%.

2.Energy Savings: By lowering inlet air temperature to near wet-bulb levels, the system mimics water-cooled performance without the associated risk.

3.Closed-Loop Design: As a Closed Circuit Fluid Cooler, it prevents contamination of the process fluid, ideal for sensitive applications like data centers or industrial processes.

4.Legionella-Free: The Adiabatic Cooler’s design eliminates stagnant water, mitigating bacterial growth risks.

·Data Centers: Combines Closed Circuit Cooling reliability with Adiabatic Cooling efficiency.

·Industrial Processes: Ideal for high-heat rejection with minimal water use.

·HVAC Systems: Reduces energy costs while maintaining compliance.

Company Profile:

Bingshan Group was founded in 1930 (invested by Japan's Panasonic and the Chinese government). It currently has 43 enterprises, total assets of 9.5 billion yuan, and 12,000 registered employees. It is China's largest refrigeration and air-conditioning equipment manufacturing base, agricultural products deep processing equipment base, and one of the main bases of Sinopec general machinery equipment.

Q1.What are the products of screw compressor series?

A1:We produce includes screw type compressor,semi-hermetic compressor,hermetic compressor, Twin Screw Compressor and mycom compressor.

Q2. If the product is damaged during transportation, how do you get a replacement?

A2: First, we should investigate the cause of the damage. At the same time, we will claim or assist the buyer on our own.

Second, we will send a replacement to the buyer. The person responsible for the above damage will be responsible for the cost of the replacement.

Q3. What are your packaging conditions?

A3: Packaging: Export packaging suitable for container transportation.

Q4. Do you test all goods before delivery?

A4: Yes, we do 100% testing before delivery.