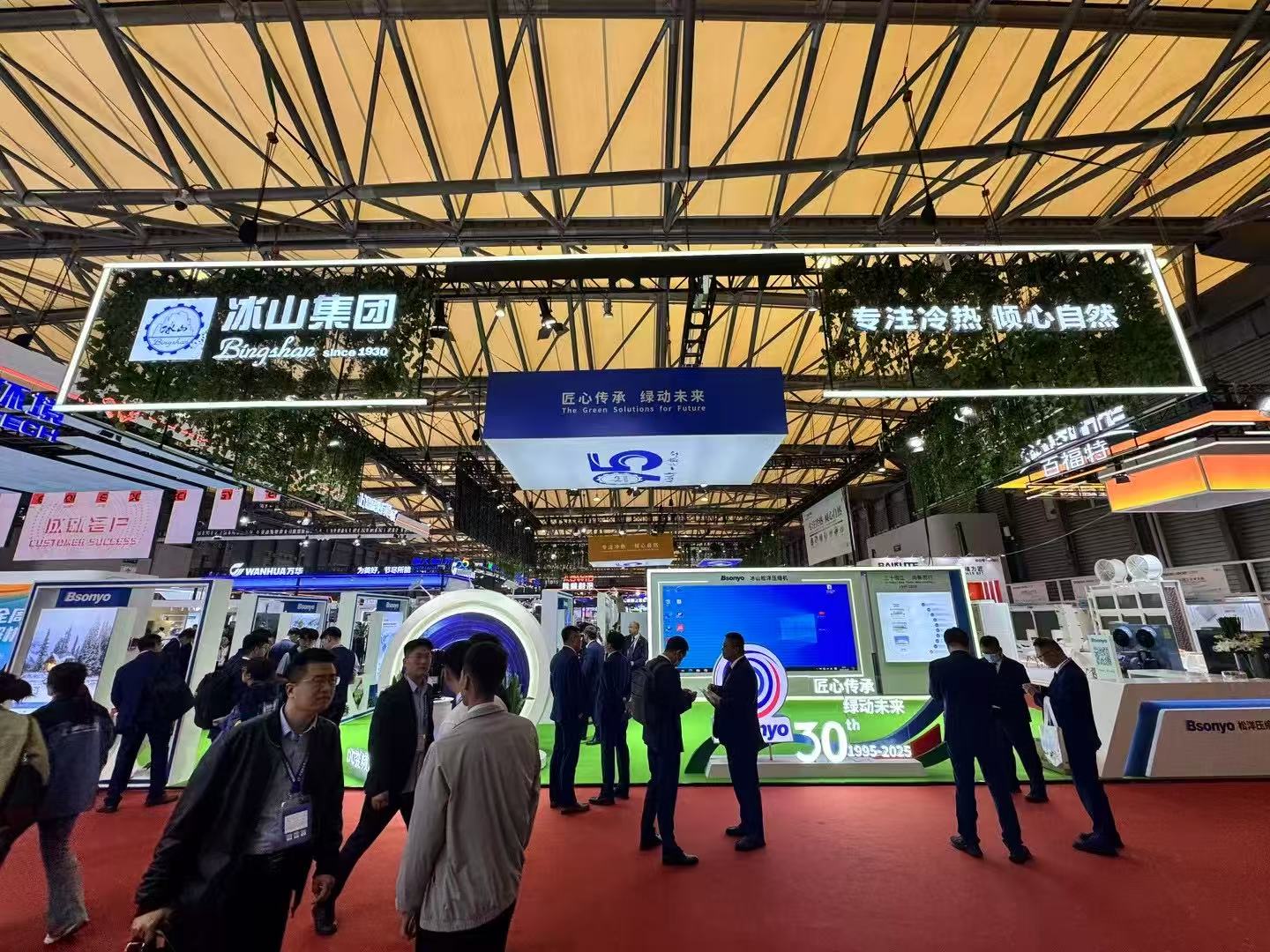

In 2025, from April 27 to 29, at the 36th China International Refrigeration Exhibition held at the Shanghai International Expo Center, Bingshan focused on the theme of "Focus on Cooling and Heating, and Love Nature" and displayed technologies and solutions in the fields of green and low-carbon cooling and heating, Smart Zero-Carbon Plant, green and low-carbon scroll compressors, and smart life at booth E1D01. Bingshan's technical experts participated in 11 forums to share innovations, including advancements in Energy-Efficient Commercial Freezers and CO₂ Transcritical System applications.

Energy-Efficient Commercial Freezers Lead Innovation

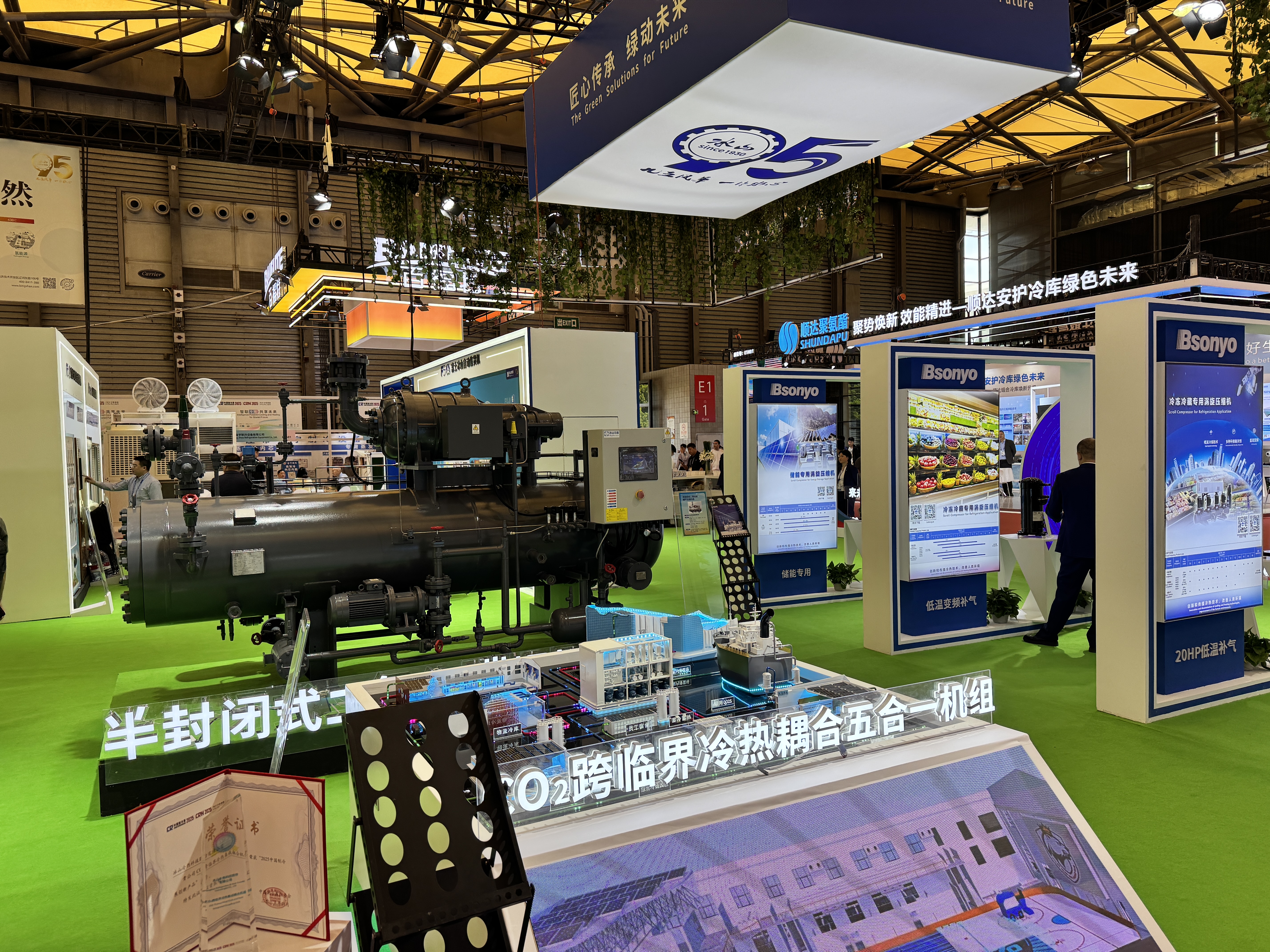

At the exhibition, Bingshan showcased a five-in-one combined cooling and heating system, featuring a semi-enclosed CO₂ screw compressor unit for ultra-low-temperature scenarios (-30℃ to -52℃) in food, aquaculture, and scientific research. Highlights included:

A new-generation dual-stage unit for mining and tunnel drilling, reducing energy consumption by 15%.

Smart hybrid air source heat pumps for commercial HVAC, alongside low-noise vortex condensing units for supermarkets and cold storage.

A dry-wet cooling tower model for metallurgy and industries.

The CO₂ Transcritical System-enabled cold/heat coupling unit, applied in projects like Sam’s Club and Dalian Ice Bear Sports Center, uses natural refrigerants (zero ozone impact) to deliver -50℃ to 80℃ range efficiency, boosting annual energy savings by 15–20%.

CO₂ Transcritical System: Powering Green Transition

Bingshan’s sandbox display highlighted carbon-reduction technologies for the coal industry, including waste heat recovery and CO₂ capture across mining, coking, and chemical processes. The Smart Zero-Carbon Plant concept integrates these solutions with intelligent lifecycle services, ensuring sustainable industrial upgrades.

Smart Zero-Carbon Plant & Cold Chain Logistics

The exhibition debuted the world’s first ship-based CO₂ capture (OCCS) system, leveraging R744 (CO₂) refrigerant and transcritical technology to liquefy and store 44,000 tons/year of CO₂ (99.7% purity). This innovation extends hull lifespan by 12 years while supporting green shipping.

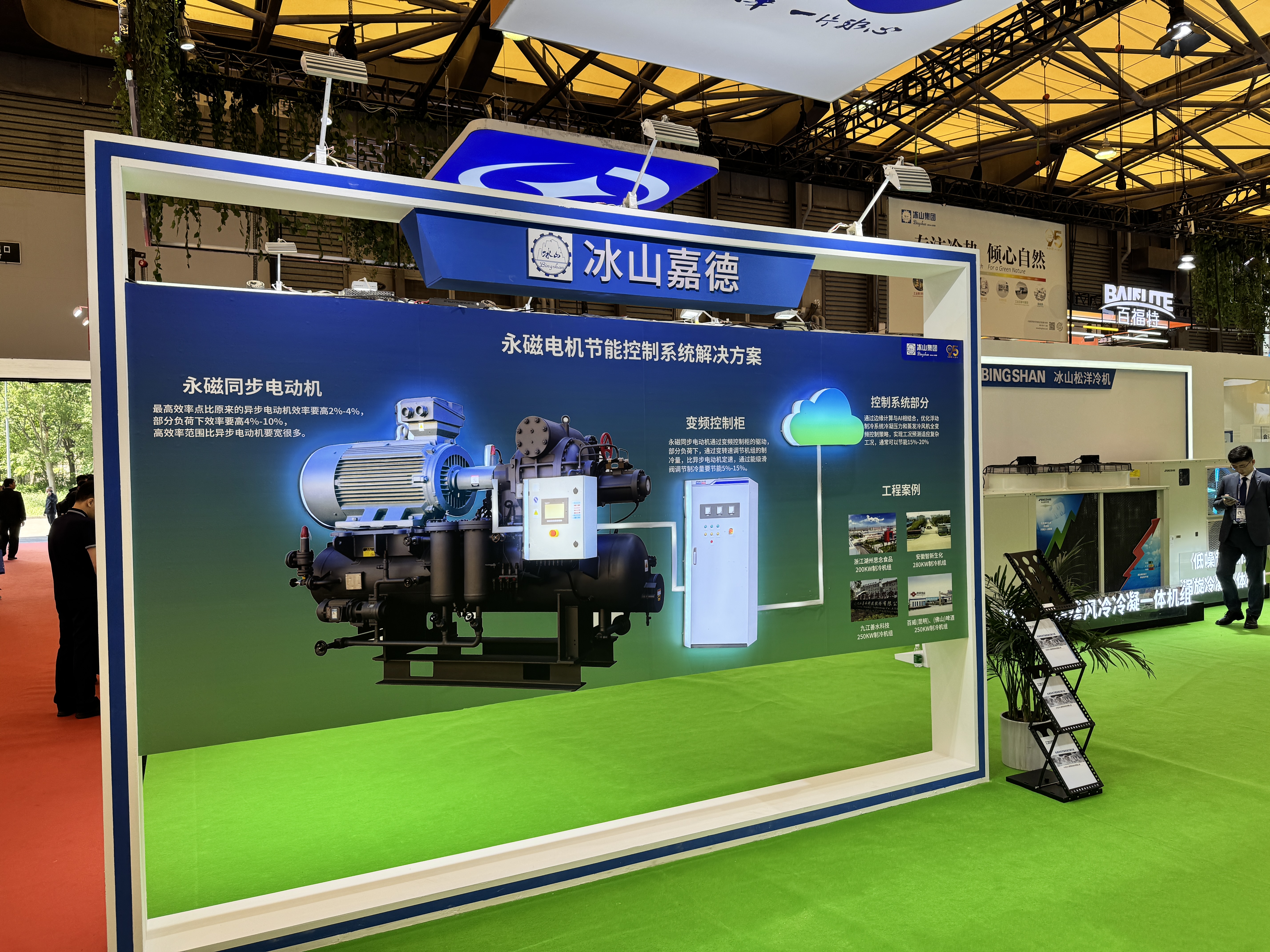

Permanent Magnet Motor Energy Saving & Digital Upgrades

Bingshan’s smart refrigeration units now feature Permanent Magnet Motor Energy Saving technology, optimizing partial-load efficiency via variable frequency control and condensing pressure adjustment. The industrial IoT platform enables predictive maintenance, energy management, and anti-counterfeiting—key for Cold Chain Logistics modernization.

Promote the intelligent iteration and upgrade of the industry. At this exhibition, Bingshan will showcase new solutions for digital energy saving. The newly launched smart refrigeration unit permanent magnet motor energy-saving solution combines laboratory and actual case data experience, and utilizes the improvement of permanent magnet synchronous motor efficiency and speed to achieve the energy-saving effect of partial load variable frequency adjustment of cooling capacity and floating refrigeration system condensing pressure. Relying on the industrial Internet platform, Bingshan provides full life cycle services for the refrigeration and air conditioning aftermarket, provides comprehensive energy management solutions, realizes fault prediction, smart inspection, and Internet logo secondary analysis and anti-counterfeiting, and contributes new value to customers.

Scroll Compressors for Diverse Markets

Bingshan’s scroll compressors cater to niche demands, including:

Ultra-low-temperature heat pumps (-42℃ evaporation) with jet enthalpy tech, improving heating efficiency by 13%.

Patented air-check valves reducing pipeline pulsation.

Oil-gas separation and radial-flexible designs enhancing motor reliability.